Comprehensive plastic manufacturing solutions for industrial needs

Explore our comprehensive range of plastic products and industrial solutions designed to meet your manufacturing needs.

Professional chiller systems and cooling solutions designed to maintain optimal temperatures for industrial plastic manufacturing equipment and processes.

High-Performance Industrial Chiller

Efficient water cooling system with scroll compressor technology designed for continuous industrial operations with precise temperature control.

Wide Range Cooling Solution

Specialized brine chiller system utilizing glycol and methanol solutions for extreme temperature applications in industrial operations.

Compact Cooling Solution

Efficient air-cooled chiller system with scroll compressor technology perfect for applications where water supply is limited or unavailable.

High-Capacity Cooling System

Compact semi-hermetic/open screw compressor system delivering economized cooling for large-scale industrial applications with superior efficiency.

For Batching Plant

Specialized chiller system designed for batching plants with air-cooled or water-cooled capabilities, handling high capacity cooling requirements.

Heavy-Duty Cooling Solution

Robust water-cooled screw chiller system with semi-hermetic/open screw compressor delivering economized, high-capacity cooling for industrial operations.

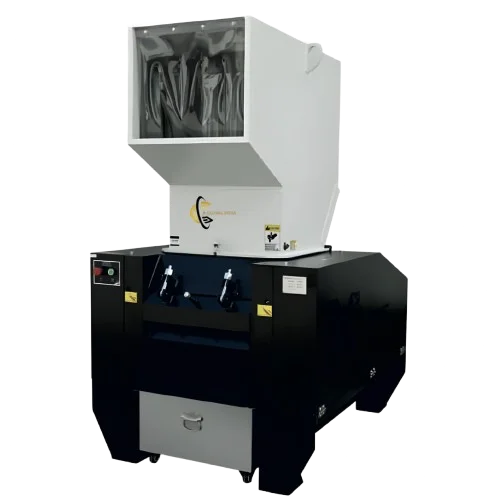

Advanced industrial machinery solutions for plastic processing, recycling, and material handling with precision engineering and safety features.

High-efficiency plastic granulator with unique scissors-type cutting structure, ideal for processing large-scale hollow products, leather, PE film, PET bottles and other materials.

Specialized flake blade design for crushing general plastics, sheets, tubes, and profiles with precision.

Patent-designed front-positioning blade system optimized for hollow materials like bottles and barrels.

NG-GM series designed for instant recycling of sprues and runners with minimal noise and powder generation.

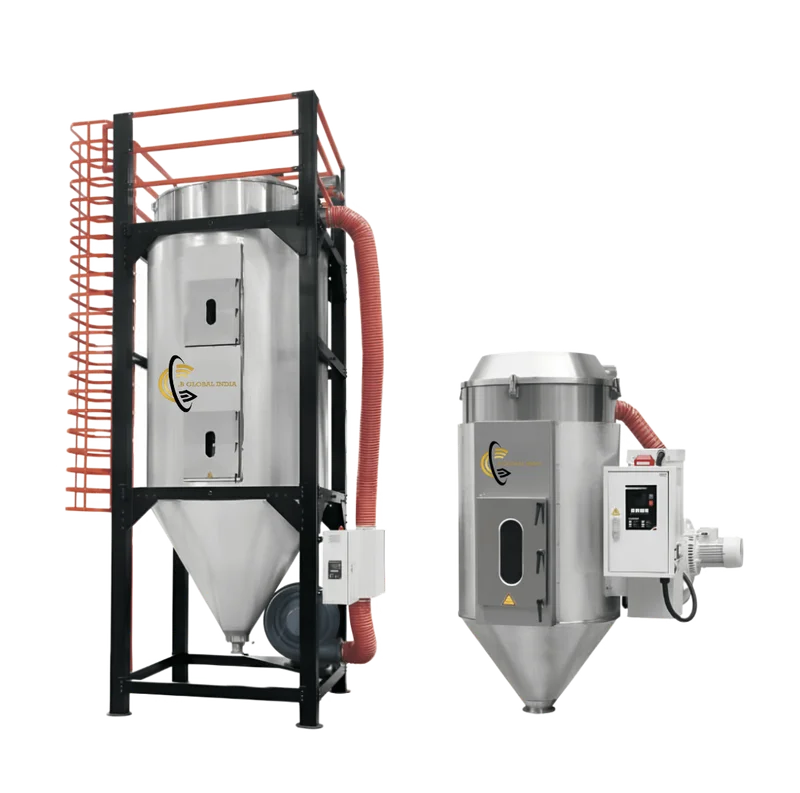

Hot air down-blowing design with double-layer insulation for efficient engineering plastic drying.

High-performance hot air diffusion with precision temperature control and 24-hour automatic operation.

Carbon brush motor system with cable remote controller and cloth-type filter with auto-cleaning function.

Compact design with low weight, wire-controlled operation and material shortage alarm features.

Specially developed for large material volumes, long conveying distances, and crushed materials. High-power motor with enlarged hose and hopper featuring reversing function and automatic dust removal.

Compatible with all granulator series, automatic material collecting without manual involvement.

Automatically separates powder from granulated output with vacuum suction and dust removal function.

High-speed helical mixer for fast and even blending of masterbatch with all plastic materials, featuring stainless steel construction and optional heating capabilities.

Compact four-wheel mobile mixer with cycloidal pinwheel reducer motor, designed for fast and efficient color mixing with low energy consumption and adjustable mixing time.

Specialized mould manufacturing and design solutions for diverse industrial packaging and product applications. View our gallery of mould solutions by category.

50ml to 250L containers for chemical products

Premium cosmetic and personal care containers

High-quality pharma containers and vials

Durable containers for pesticide products

High-precision medical device moulds

Custom caps and closure systems

Large capacity drum containers for liquids

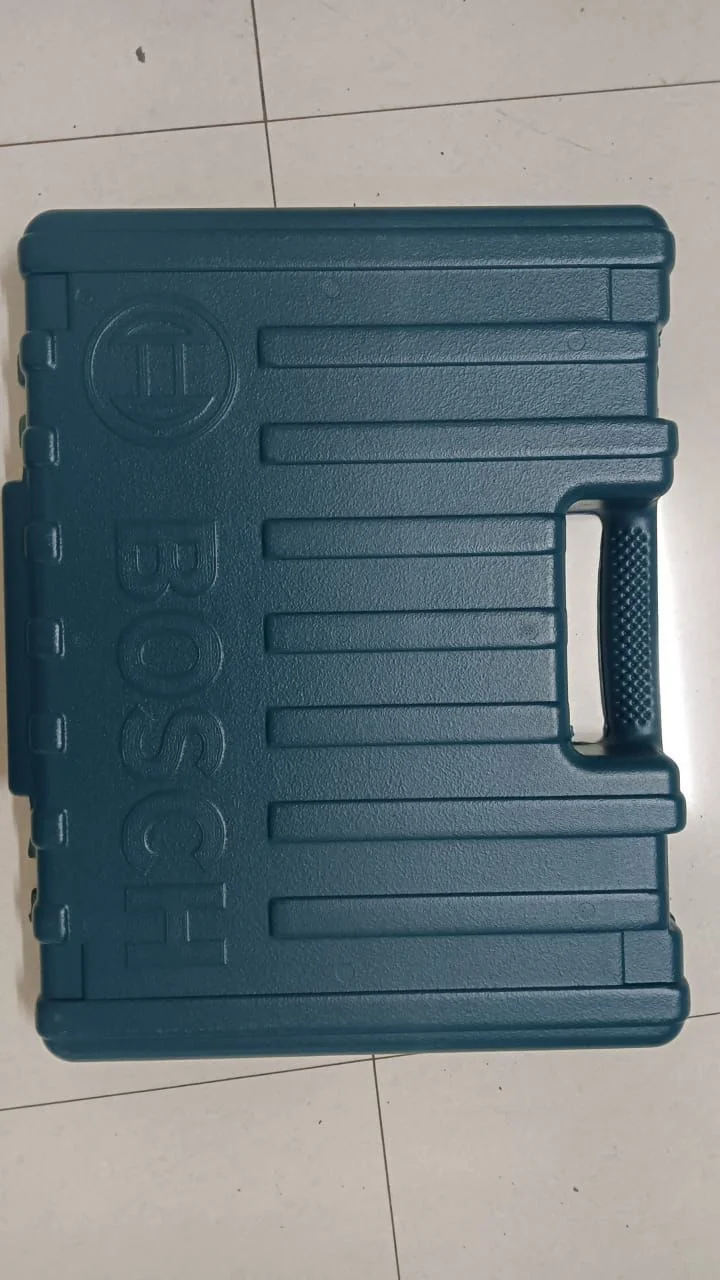

Durable and functional tool storage solutions

High-quality plastic bottles manufactured using advanced blow molding technology, available from 50ml to 1000L capacity.

Durable plastic water tanks for residential and industrial applications with superior structural design.

Precision-manufactured injection molded components for various industrial applications.

Specialized plastic floats for solar panel installations, designed for durability and stability in water.

High-quality plastic flower pots, planters, and garden accessories manufactured with precision.

Specialized plastic components for automotive industry applications with high durability standards.

Discover how CB Globle India's comprehensive solutions can elevate your plastic manufacturing capabilities. From machinery procurement to training and consulting, we're here to support your success.

Get in TouchWe specialize in creating tailored product and machinery solutions for your specific industrial needs

Get In Touch Learn About Consultancy